Your logo is exposed onto a mesh screen and any blank areas in the design are coated with an impermeable substance, which means no liquids can pass through, then a squeegee pushes ink through the screen and your items are branded.

Pros: Cost-effective if you have large quantities to brand, great for large and bold logos and colours are printed one at a time to ensure accuracy. Allows for single or up to 6 multicolour branding.

Ideal for bags, t-shirts, umbrellas, coolers and other smaller items like notebooks and folders.

It is the art of decorating fabric with designs with strands of thread. In the case of branding, it is done by computers that read digital formats of your design and then recreating it directly onto your product.

Pros: A classic decoration technique that creates a high-value look. Can be done for both single and multi-colour logos. Is suitable for branding of both flat and curved surfaces.

Ideal for any type of clothing and headwear items, like shirts or peak caps, as well as other textile gifts like bags.

Authentic Material: Made from 100% genuine leather for unparalleled quality.

Craftsmanship: Expertly stitched and finished for a refined look.

Versatility: Available in various sizes and shapes to suit any style.

DTF stands for Direct to Film and refers to a digital printing technique used to apply designs to a variety of fabrics and substrates. It’s a process where a design is printed onto a special film, which is then transferred to the final product using heat and pressure. This method is versatile, allowing for printing on cotton, polyester, blends, and even non-textile materials like leather and nylon.

Pros: Requires no screens and minimal space. Only a small amount of ink is required to achieve a lot of detail. No mess.

Ideal for garments that are ready for Digital Garment Printing.

Your logo is digitally printed with full colour onto special transfer paper that’s cut to size and branded onto your product by means of heat.

Pros: Ensures realistic full-colour prints and flexibility of the product is not compromised, unlike which is possible with heat press.

Please Note: Only suitable for white products made from at least 60% polyester and products coated with a polymer.

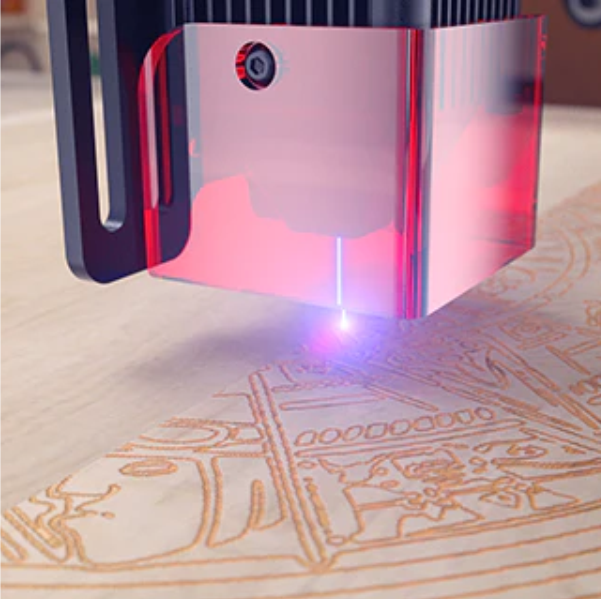

The process of etching your logo into a product by ‘burning’ off the top layer of the products surface to reveal a second layer underneath.

Pros: Creates a subtle yet elegant permanent impression on the product at high speeds and incredible accuracy. Great for logos with minute detail.

Please Note: If the second layer is a different colour, that colour will be exposed when engraving. Ideal for awards, stainless steel accessories, flasks, pens and mugs, to name a few.

Depending on the material of your product, there are three types of lasers used:

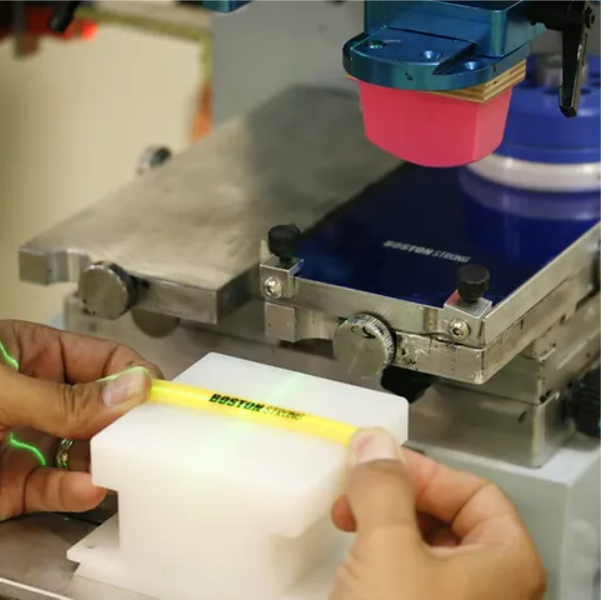

An offset printing process that involves ink being transferred from a plate to a rubber or silicone sheet and only then applied to the product. Offset refers to when the design is transferred from one surface to another before it reaches the product.

Pros: It’s a fast, economical and commonly used branding method, can be applied to and conforms to almost any shape and allows for single or multi-colour branding (up to 4 colours).

Ideal for small plastic items such as keyholders, pens, torches and USB’s.